For detailed information, other images and documents, please select individual articles from the following table.

VMU plus chemical injection mortar

The universal injection system for cracked and non-cracked concrete, solid and perforated brick masonry and retrofitted reinforcement attachment (does not apply to the 300-ml cartridge)

Available in 3 versions

Prices for customers after login

Register now and access more than 40,000 products

Variants

Register now and access more than 40,000 products

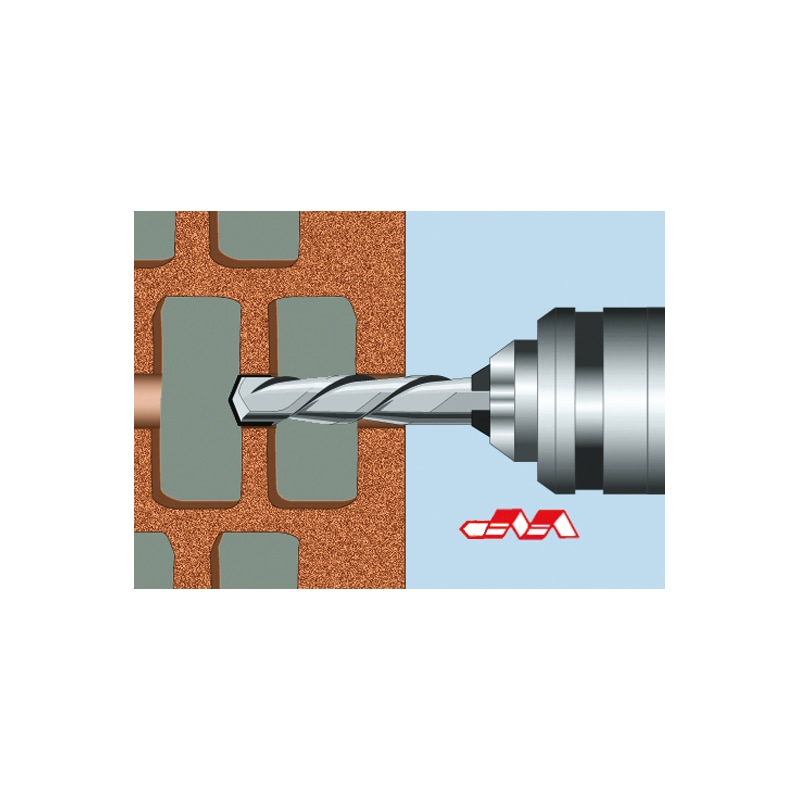

The universal injection system for cracked and non-cracked concrete, solid and perforated brick masonry and retrofitted reinforcement attachment (does not apply to the 300-ml cartridge)

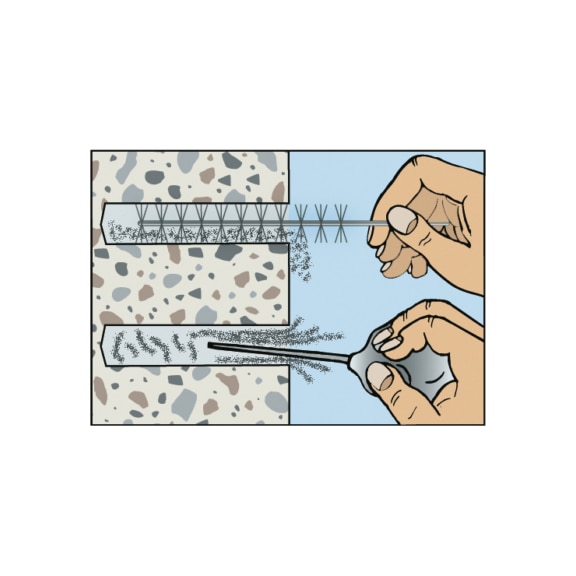

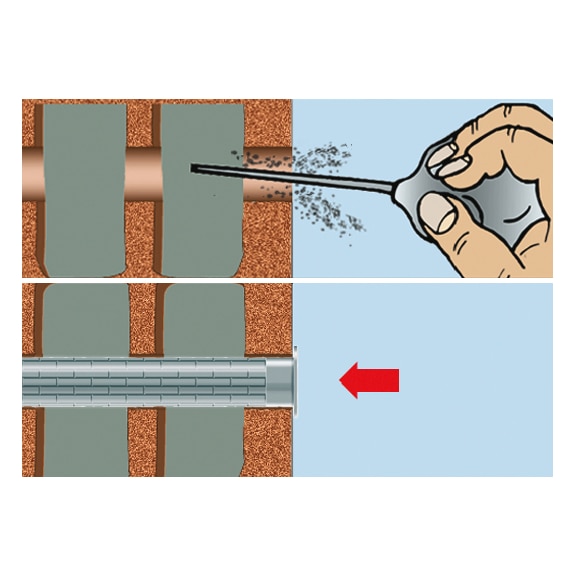

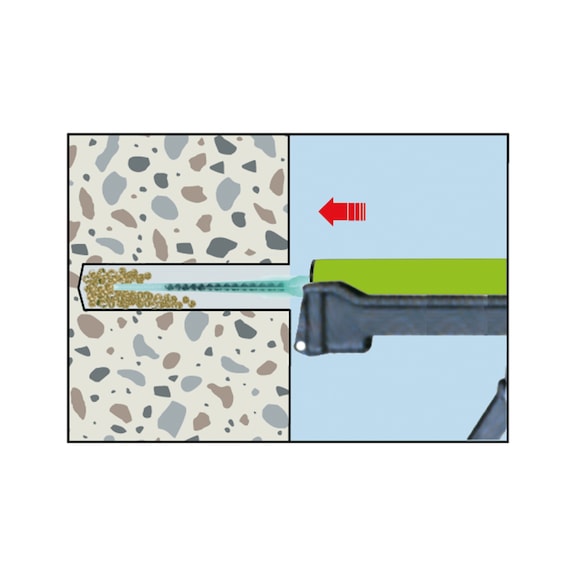

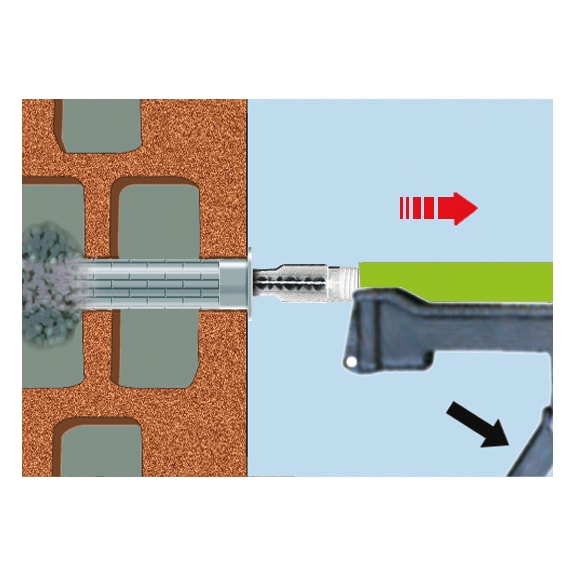

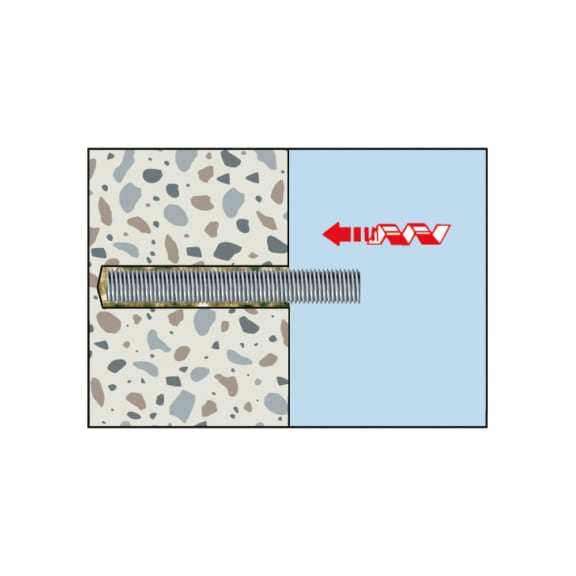

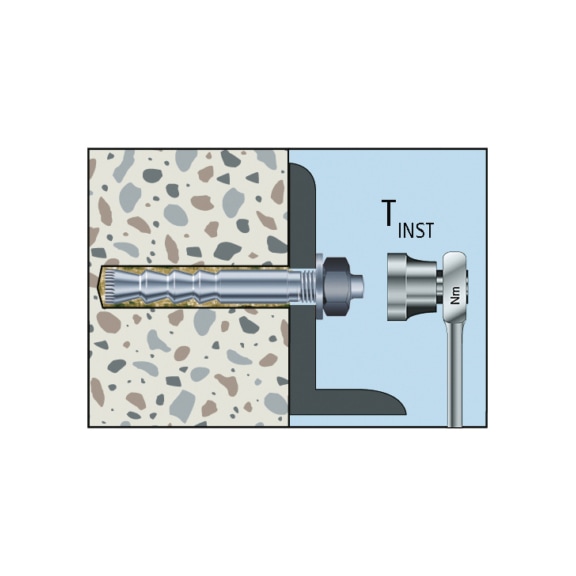

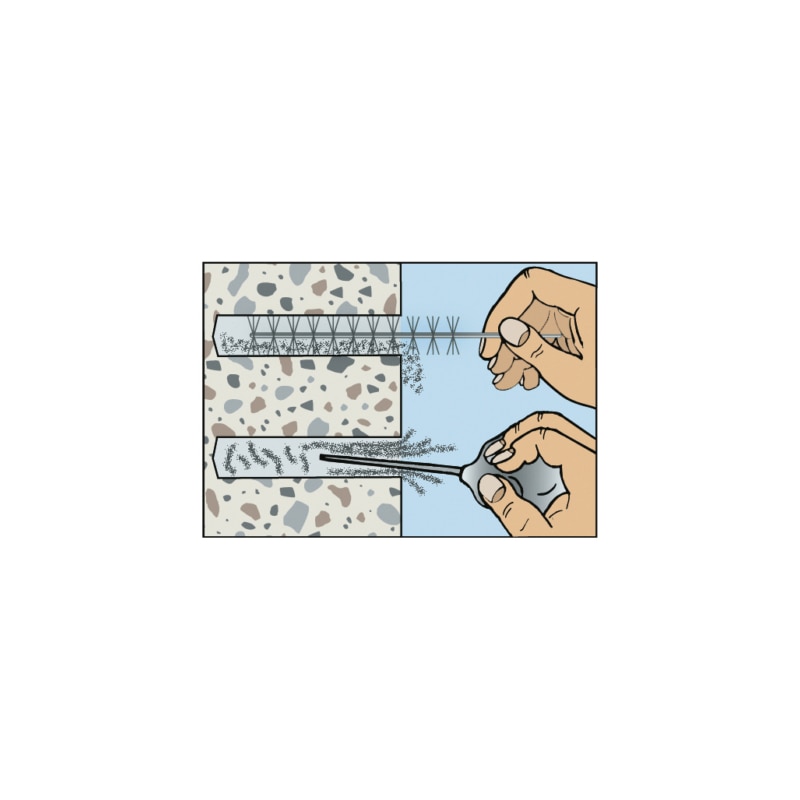

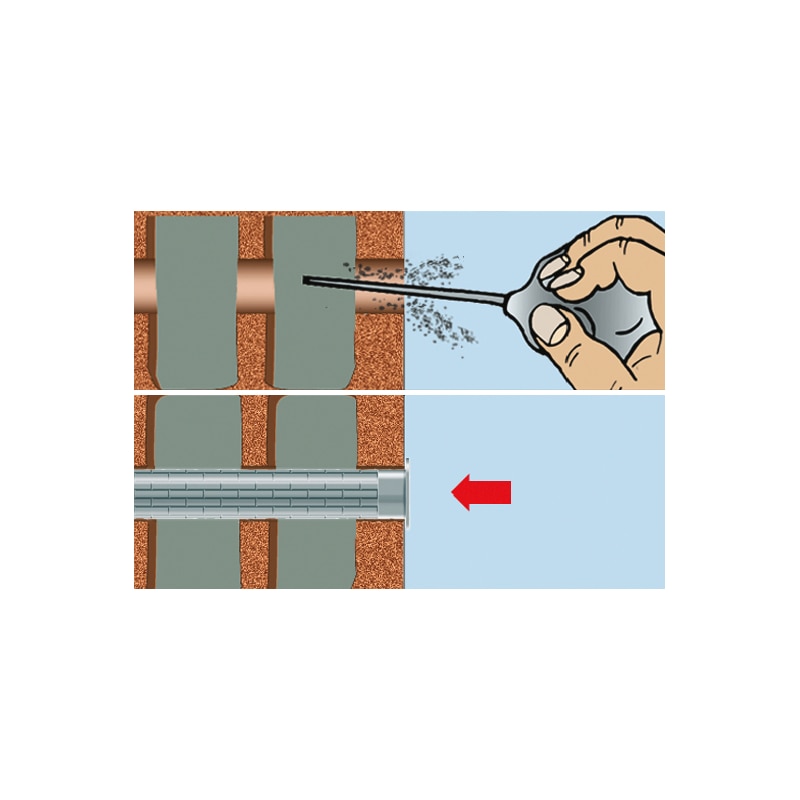

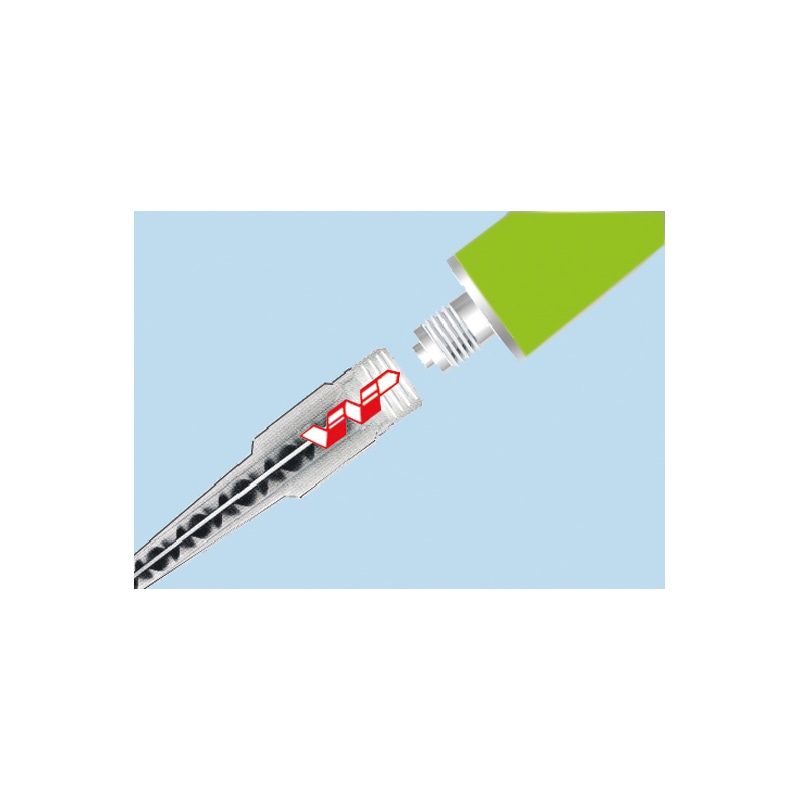

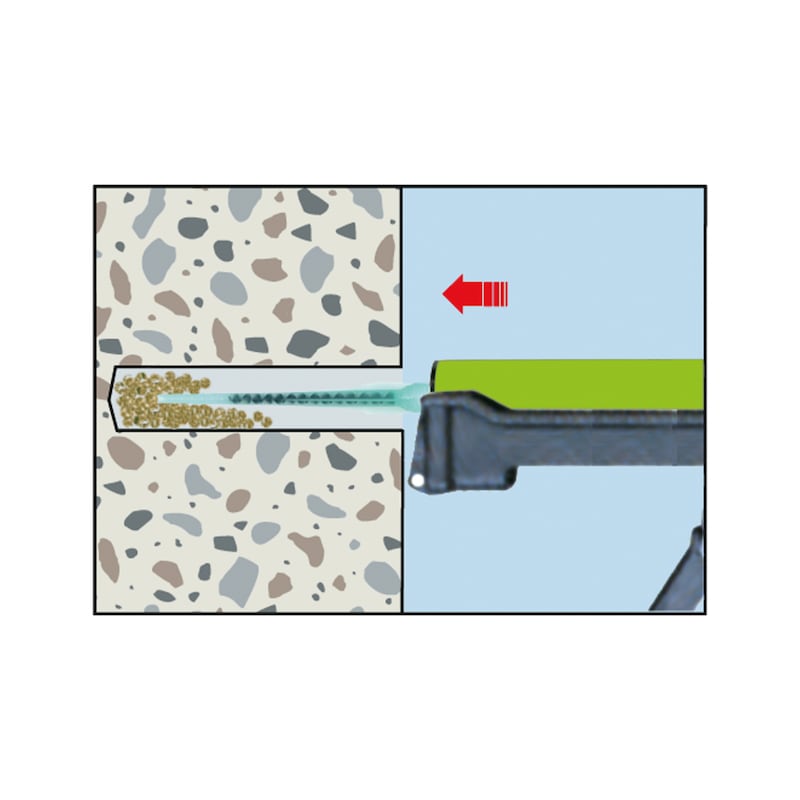

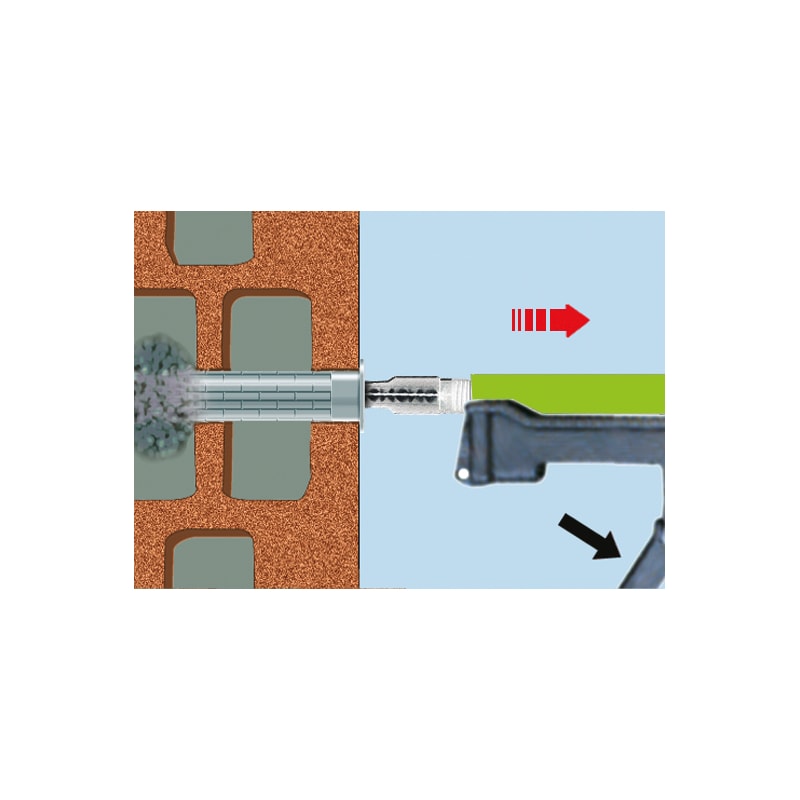

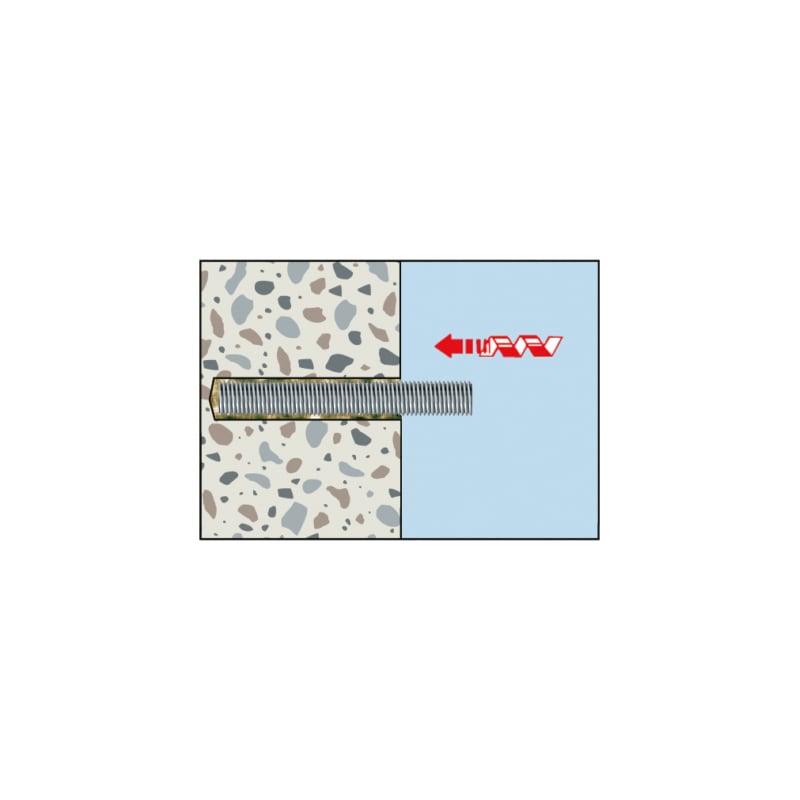

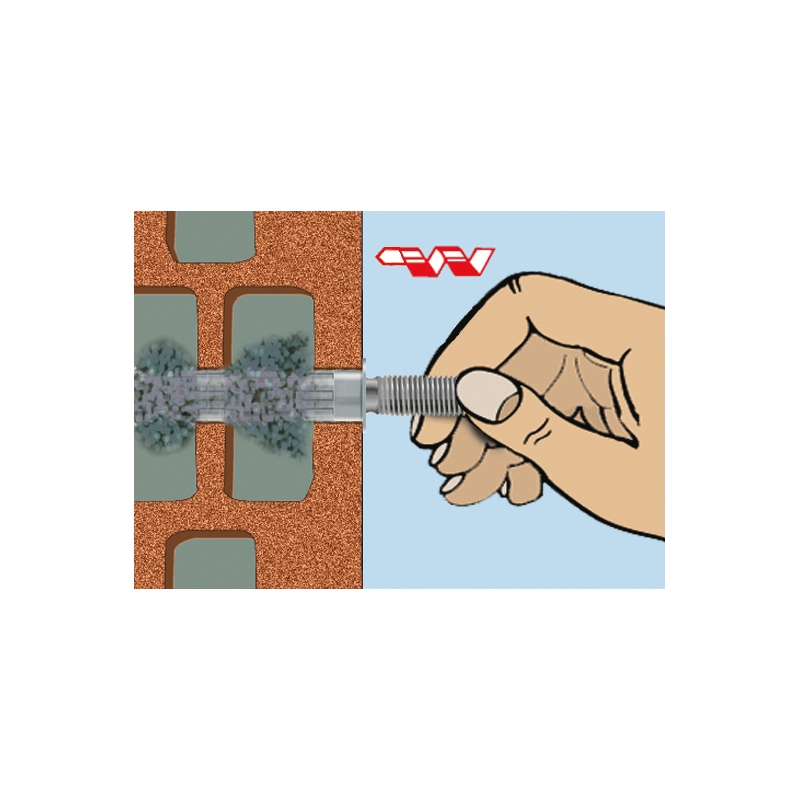

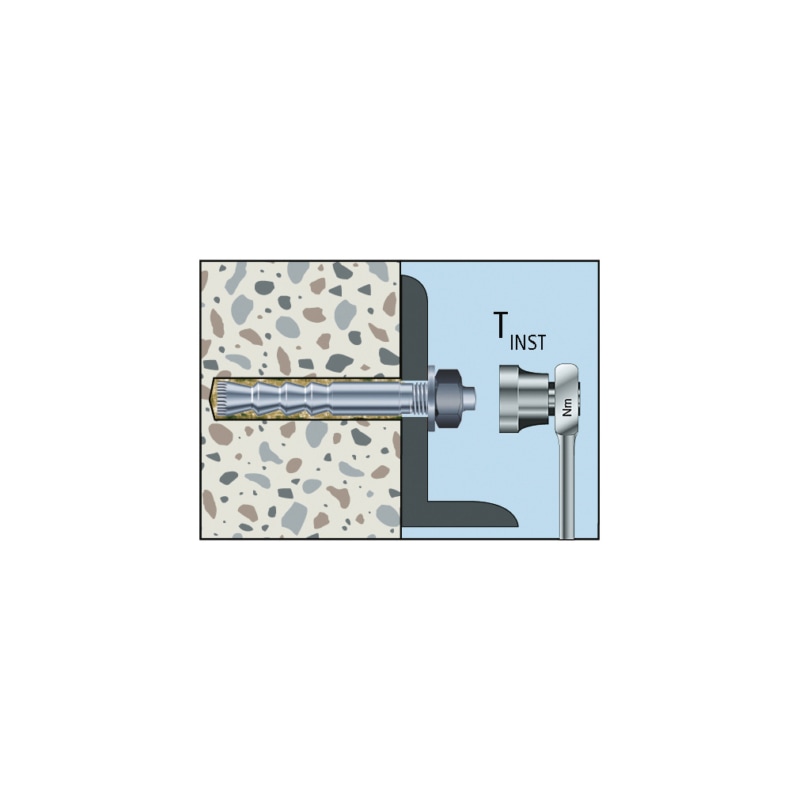

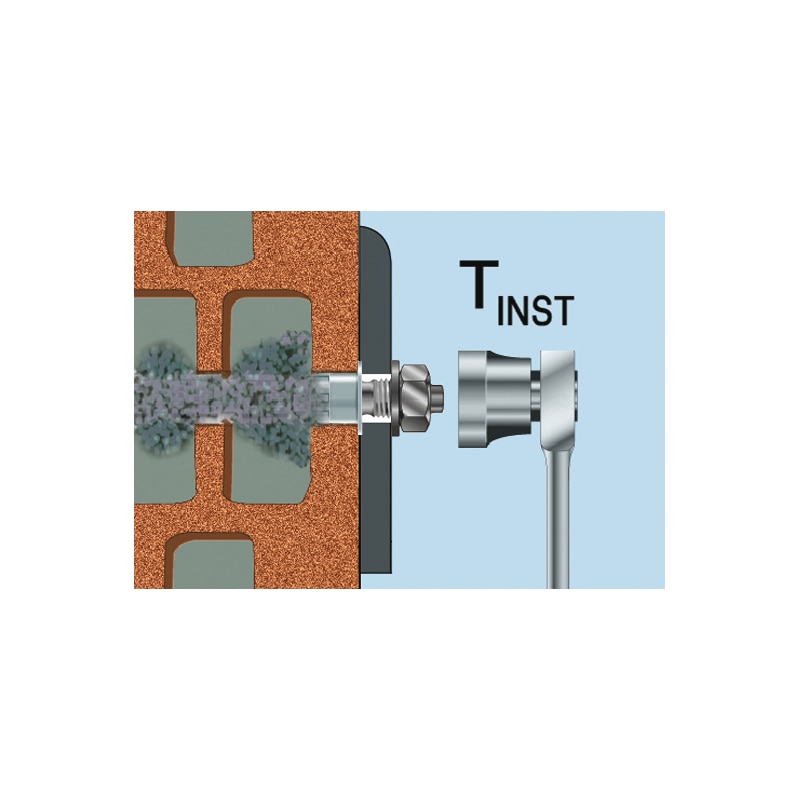

The VMU plus injection system is a bonded anchor system, comprising the two-component,

styrene free composite mortar VMU plus and various system components that must be used depending on the building material and application.

Field of Application:

For anchoring heavy loads such as steel beams, steel supports, brackets, awnings,

façades, canopies etc. in cracked and non-cracked standard concrete with a strength class ≥ C20/25 and ≤ C50/60, masonry made of solid brick and perforated brick.

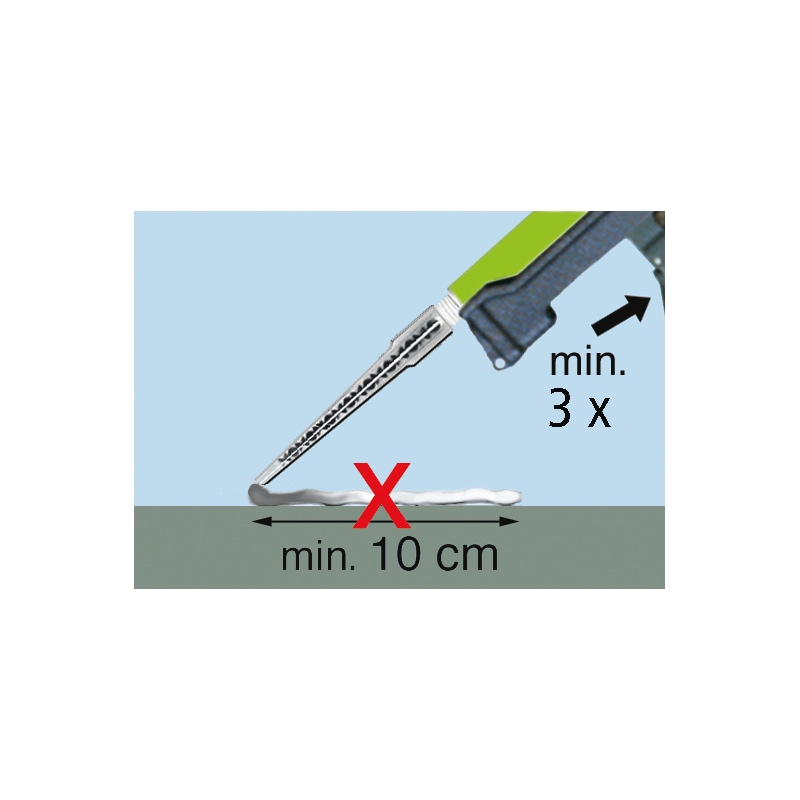

Advice:

The tubular film cartridge (0911 003 300) must be cut open before use. To do this, pull the foil on the thread outwards and cut using scissors.

Advantages:

- Just one chemical injection mortar for virtually all applications, ensuring greater flexibility,

- reduced stock and increased application reliability

- Approved for cracked (M 8 to M 30) and non-cracked concrete (M 8 to M 30)

- Approved for post-installed reinforcement attachments (Ø 8 to Ø 32)

- Approved for use in wet concrete and boreholes that are filled with water (M 8 to M 16)

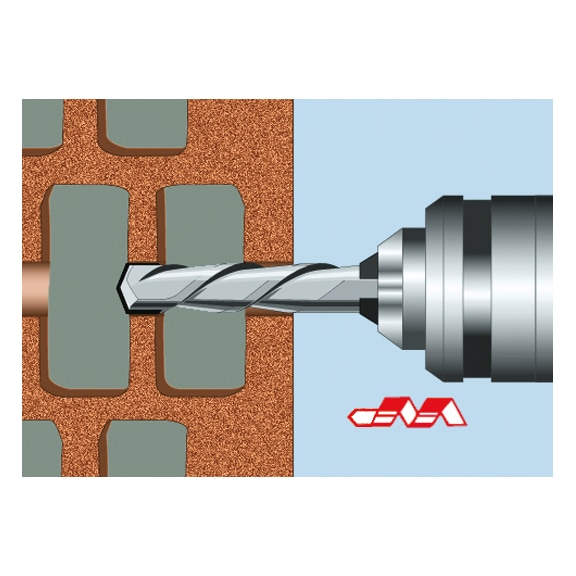

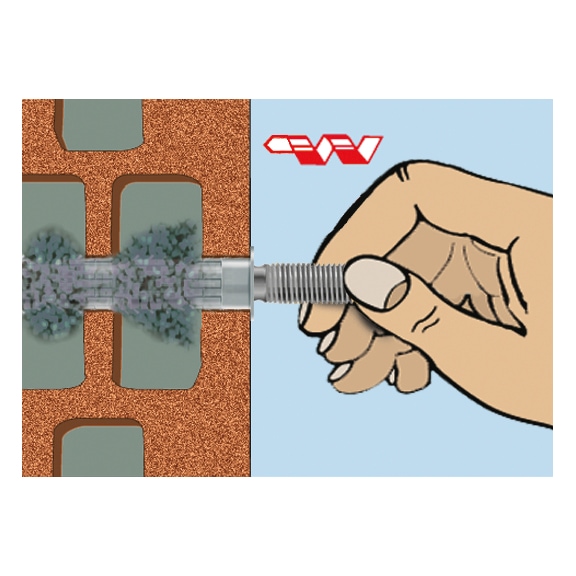

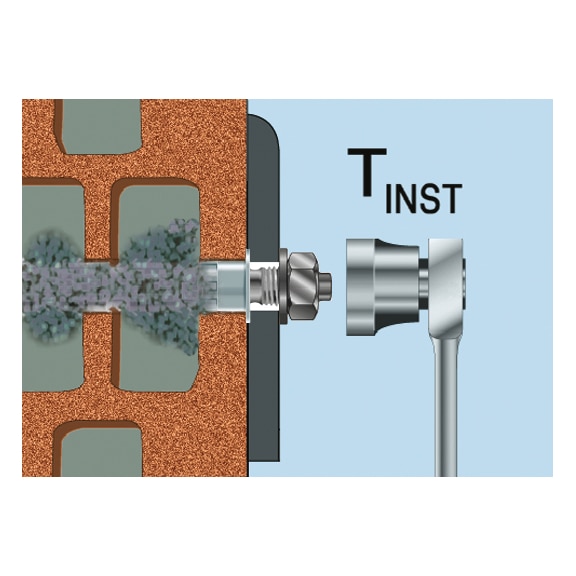

- Approved for solid and perforated brick masonry

- Approved for conventional threaded rods with proven strength (acceptance test certificate 3.1)

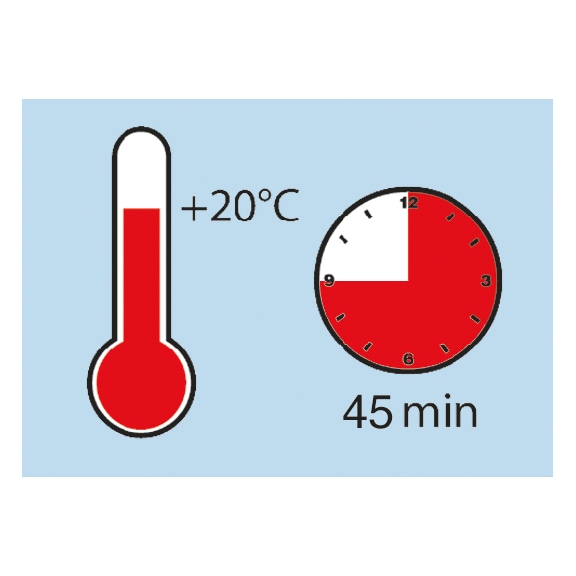

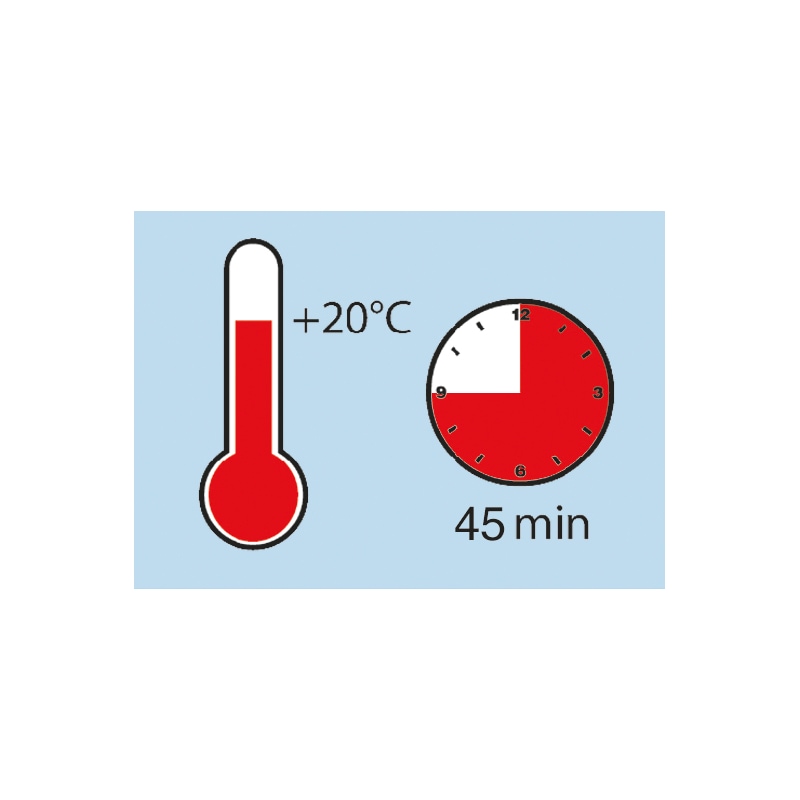

- Substrate temperature during application: -10°C to +40°C (concrete)

- Ambient temperature once fully cured: -40°C to +120°C (in concrete)

- Variable anchoring depths for added flexibility

- Fire protection test

- Opened cartridges can continue to be used with a new mixer nozzle

- Styrene-free two-component vinyl ester-based mortar

- Approved for use during seismic activity in performance category C1 (M 8 to M 30)

- Products bearing the NSF logo have been tested and registered by the National Sanitary Foundation (NSF). NSF is the only international registration that guarantees that the product can be used in the food industry without posing health risks

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!