For detailed information, other images and documents, please select individual articles from the following table.

Available in 5 versions

Prices for customers after login

Register now and access more than 40,000 products

Variants

Register now and access more than 40,000 products

Field of Application:

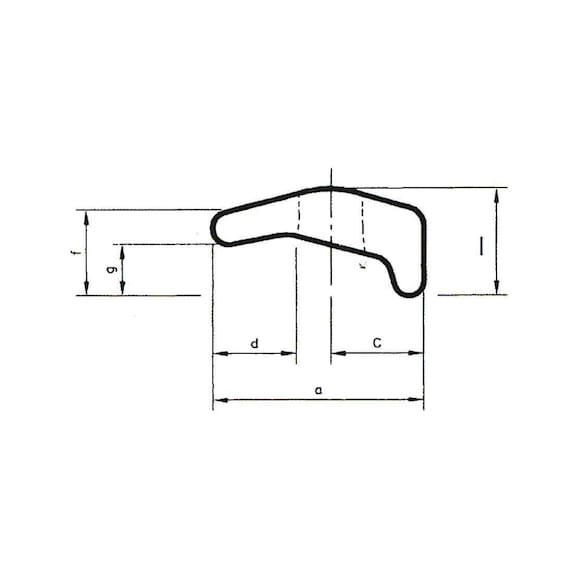

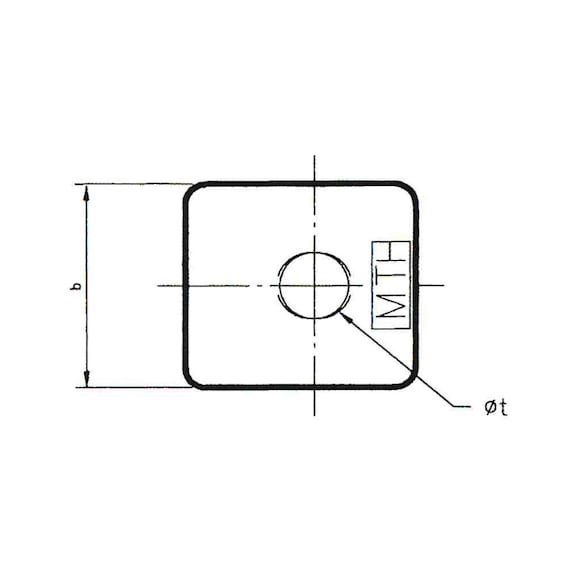

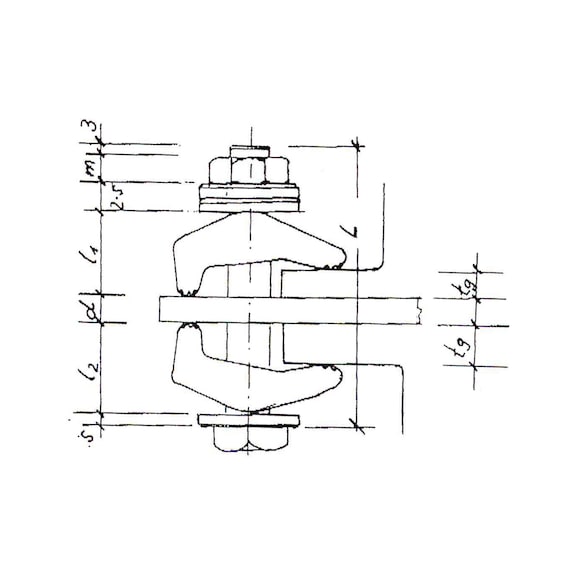

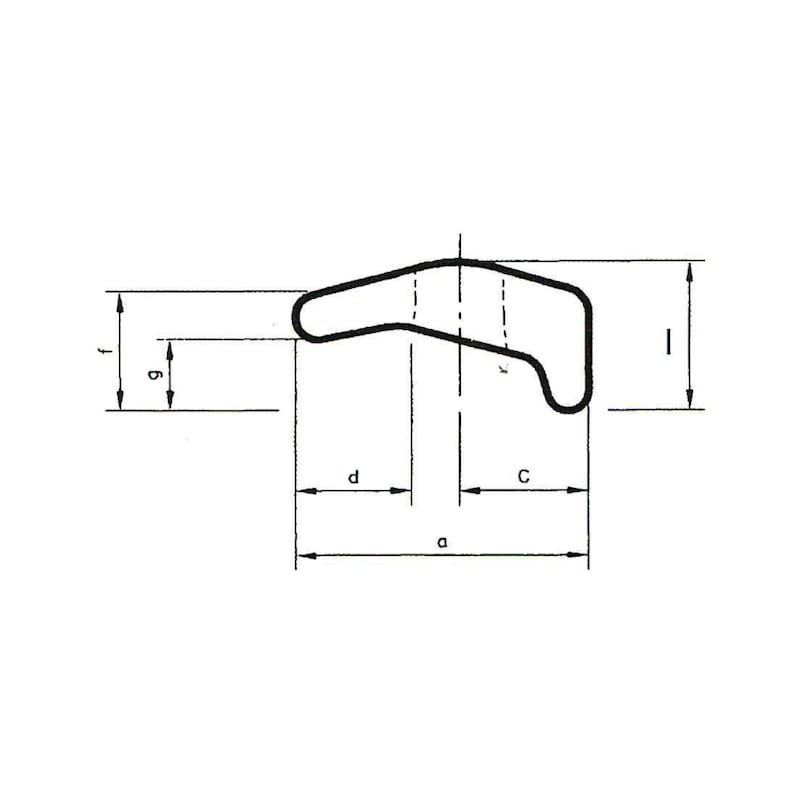

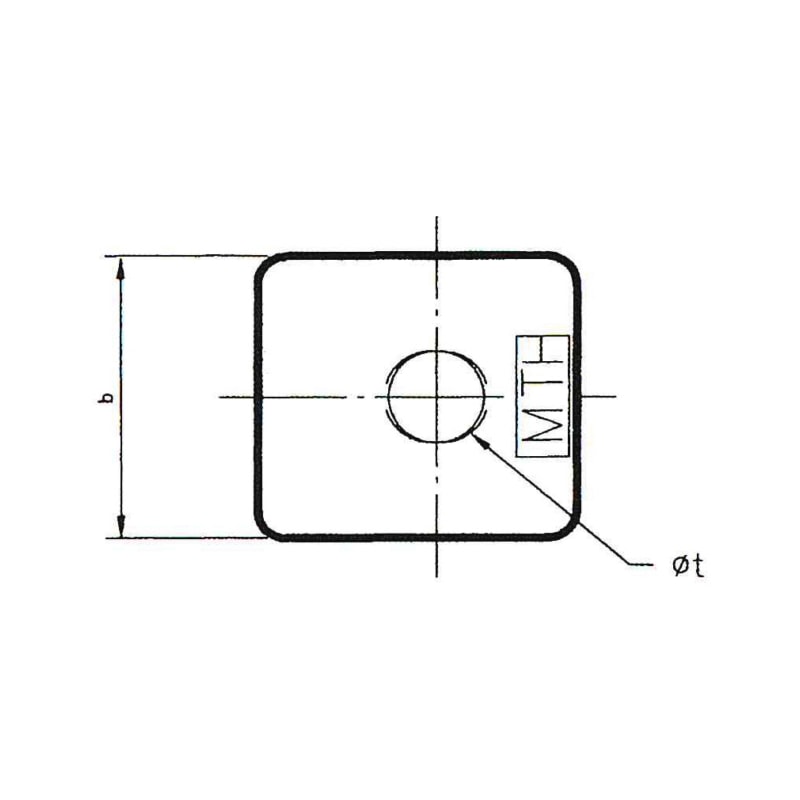

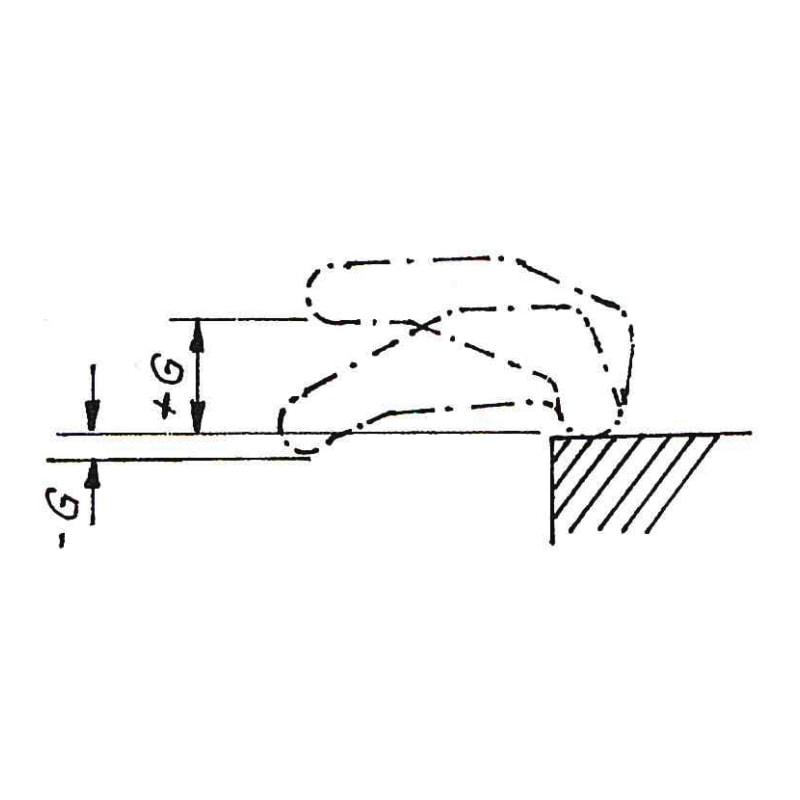

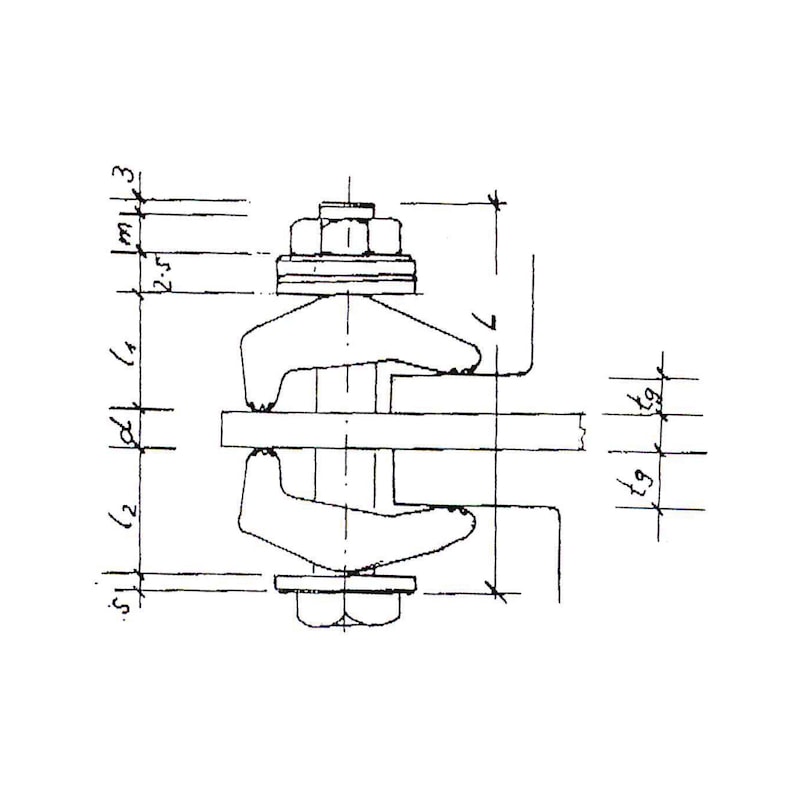

The support clips are used to connect and transmit load from intersecting beams of various shapes and dimensions and to securely fasten additional steel construction components to available structures. It is also possible to connect beams that lie on top of each other if the flanges are of the same width.

The selection of suitable support clips depends on the steel beams used. When planning steel structures, DIN 18800-1:1990-11 (DIN EN 1090-1 from 01/07/2014) and DIBt (Deutsches Institut für Bautechnik - German institute for civil engineering) approval Z-14.4-483 must be taken into account with respect to the Nova Grip support clips. The bolts must comply with strength class 8.8 or 10.9 in accordance with EN ISO 898-1:1999 and the nuts with strength class 8 or 10 in accordance with EN 20898-2:1993.

DIN 18800-7:2002-09 (DIN EN 1090-2 from 01/07/2014) is applicable for protecting the support clip connection against corrosion. Use in harsh environments is permitted. However, the zinc coating on the support clips and spacer pieces must not be damaged and the steel structure must be checked. At the first sign of corrosion, the protective surface layer must be completely or partially replaced. Use of support clip connections is permitted in structures that are predominantly subject to windy conditions or in components where vibrations may arise as a result of strong winds.

Advantages:

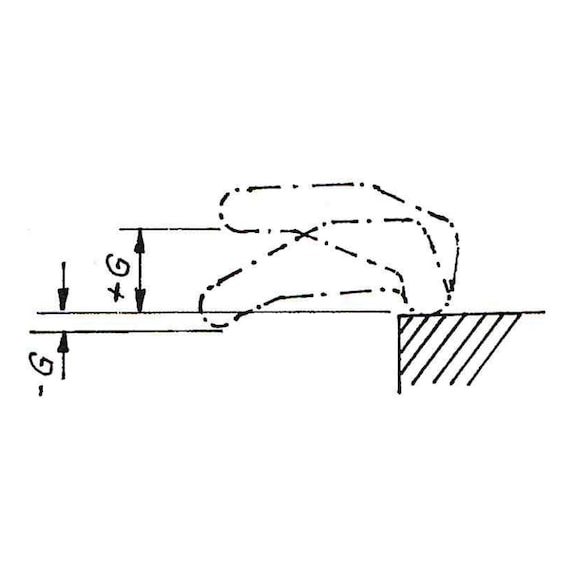

- Quick and simple installation

- Flexibility on the construction site

- Adjustable on site, which means the user can react to unplanned conditions

- No welding or drilling, enables use in "Zone 0" (this is an area in which the dangerous, explosive atmosphere as a mixture of air and flammable gases, vapours or mists is present constantly, over long periods or frequently).

- During installation, no damage to the existing surface coating

- Tested load specifications (tensile and shear load)

- DIBt National technical approval Z-14.4-493

- MAINTENANCE-FREE

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!