For detailed information, other images and documents, please select individual articles from the following table.

Available in 4 versions

Prices for customers after login

Register now and access more than 40,000 products

Variants

Register now and access more than 40,000 products

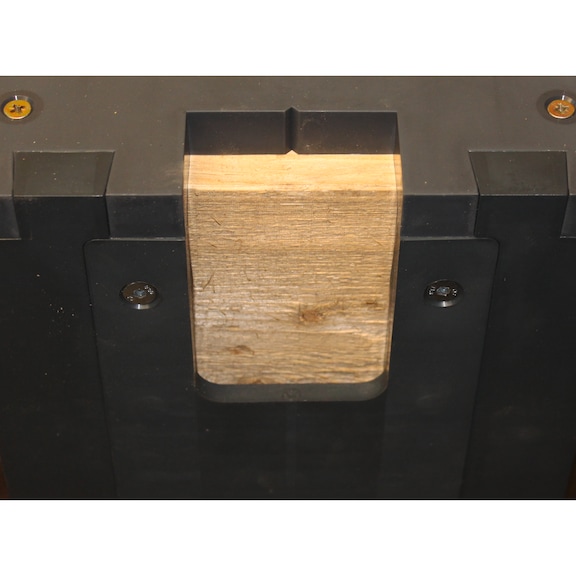

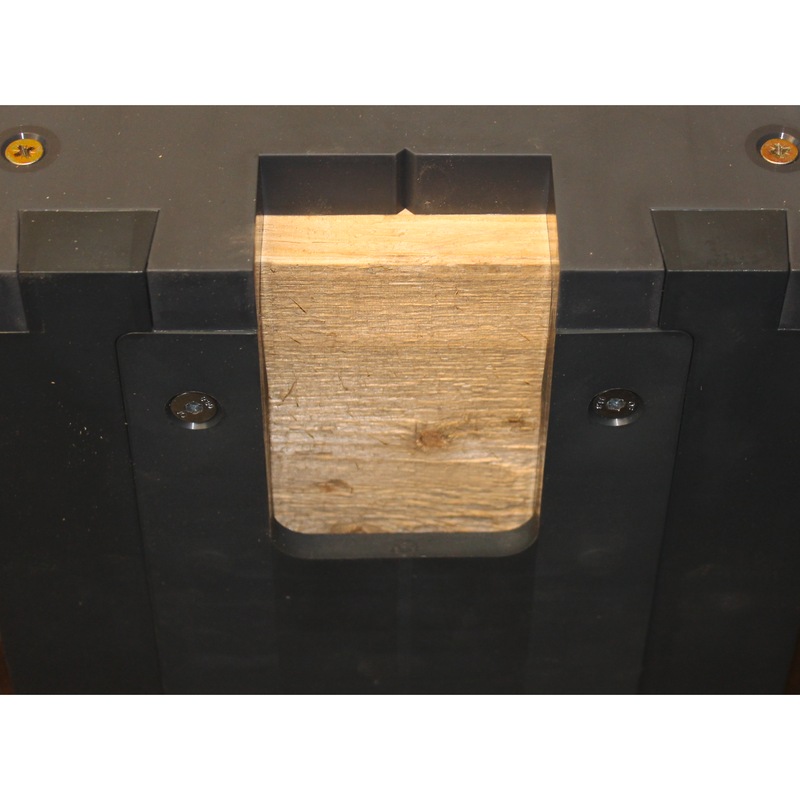

invisible

The invisible beam connectors are used for a hidden connection of main and secondary beams in which the emphasis is on a visually appealing connection.

Application area:

for concealed wood/wood connections (field of view) of secondary beams to main beams or supports

Advice:

It is advisable to use the corresponding milling template set for easy and quick pre-assembly (art. no. 0681 003 001). Using the template, the milled recess is produced at the required point on the main beam. The milling depth is 14 mm. The lower part of the connector is screwed into it. The counterpiece must be screwed into the end grain at an angle of 35°. The screw angle is determined by the shape of the tabs. Milling is not necessary in this respect. Screwing is performed with 5.0 x 80 mm full-thread screws (art. no. 0681 003 010) in accordance with EN 14592.

Installation instructions:

1. Secure the template to the beam using the fixing holes.

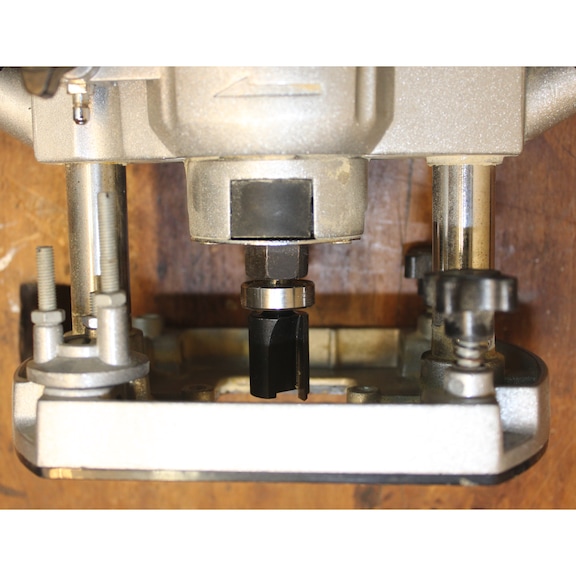

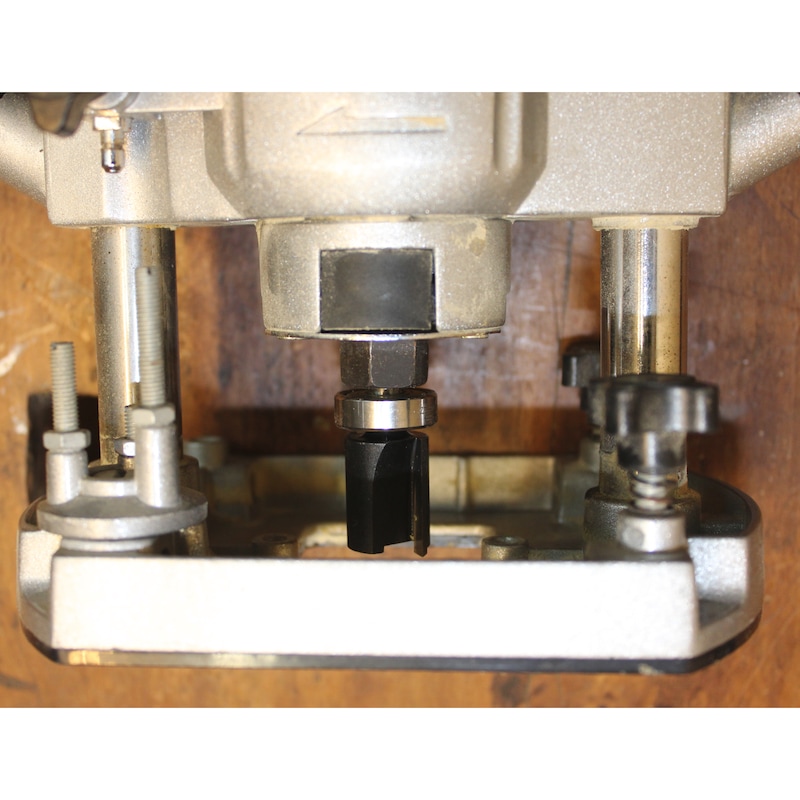

2. Set milling cutter to 14 mm milling depth. The stop ring prevents

damage to the template.

3. Mill out recess.

4. Remove template and insert base of connector.

5. Attach upper part of connector to secondary beam at centre. To do so, first position the centring screw,

then screw in the remaining screws at an angle of 35°.

6. Hang secondary beam from above.

Advantages:

- European Technical Approval (ETA-09/0301)

- High-quality appearance through concealed mounting

- High load capacity with low installation depth (14 mm)

- Self-centring and jointless pressing through tapered dovetail-like geometry

- High degree of prefabrication possible in workshop, easy and fast construction site assembly

Select RAL-colour code

!! NOTE: On-screen visualisation of the colour differs from real colour shade!!